The Ultimate Guide To Digital Printing

The Ultimate Guide To Digital Printing

Blog Article

The Of Digital Printing

Table of ContentsThe Of Digital Printing8 Simple Techniques For Digital Printing6 Simple Techniques For Digital Printing

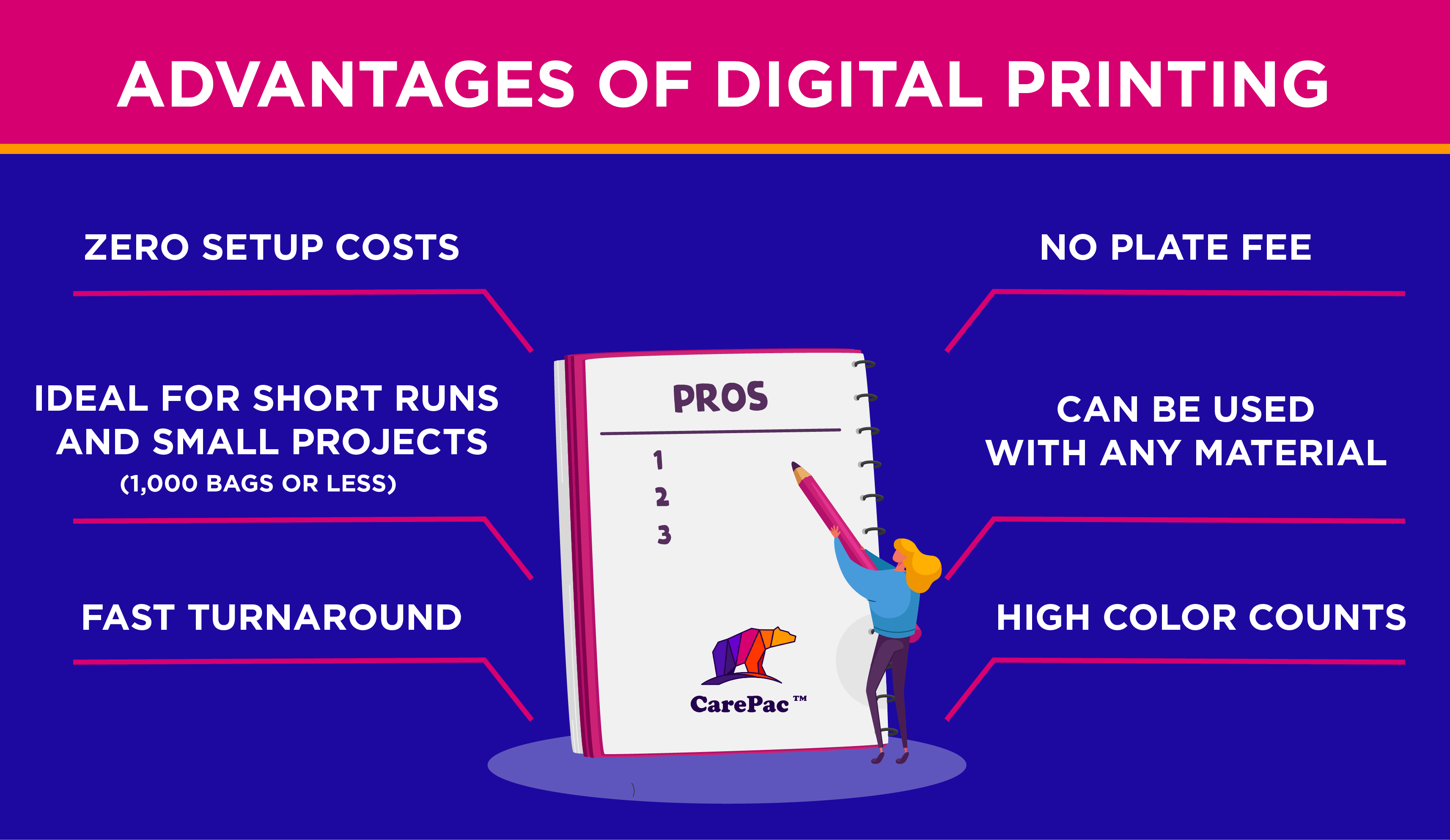

Digital printing additionally calls for marginal configuration. Right here are the key means in which electronic printing supports greener practices: One of the substantial environmental advantages of electronic printing is minimizing waste (Digital Printing). Traditional printing approaches, like lithographic printing, usually waste significant quantities of paper and ink during the arrangement phase.

Digital printing machine eliminate the need for these plates, significantly minimizing setup expenses. Digital printing presses can include variable data right into your prints, which enables for highly personalized advertising and marketing materials (Digital Printing). By personalizing your advertising products, you can boost interaction with prospective customers and enhance the opportunities of converting them right into actual consumers

Digital printing presses use outstanding color consistency and accuracy, resulting in greater high quality prints. With electronic printing, you can be certain that the shade of your prints will certainly be consistent from one print job to the next. Numerous years click this link ago, numerous customers did decline direct-injection digital printing due to the fact that the high cost. The purchase price of an established electronic printing tools is at the very least 150%of the typical printing and dyeing equipment, which increases the.

The Only Guide to Digital Printing

Printers should utilize extra fluid inks to protect against nozzle clogging and printhead failure. In order to stop corrosion of the nozzle, the ink for digital printing is extra costly than the ink for traditional printing, and added ink filtration is needed during the printing process. Furthermore, the advantage of electronic inkjet printing is obvious just when using inks with a big color range. The digital inkjet printing press almost recognizes the automated control procedure. In digital inkjet printing, the pattern is directly published on the textile, eliminating home plate making in rotary display printing. It not only saves the useful time of plate production, yet likewise conserves the additional expense of plate production. At the same time, more and a lot more brands are linked here currently a growing number of accepting of paying higher expenses for faster shipment, such as delivering a batch of materials within a week and even 3 days, as opposed to weeks and months - Digital Printing. Yes, are extra pricey than conventional printing inks, however the electronic printing process can save ink usage.

Today, the electronic direct-injection printing device has gone from proofing to the phase of medium-sized and large-sized manufacturing. The electronic direct-injection maker has actually gone with the promotion duration and went into the development and maturity duration. Both printing residences and brand name proprietors recognize the advancement potential of electronic printing, and agree to enhance investment in electronic printing. The print high quality can in some cases even competing that of balanced out printing. Digital printing is much more cost-effective for brief print runs due to the fact that it needs much less pre-press activities and less setup than balanced out printing. If an error in offset printing is not captured before home plates are made, it will be really pricey to make brand-new ones. While everyone sincerely really hopes that errors will be stayed clear of, it is sensible to prepare for their prospective adjustment. Furthermore, its accuracy is really high. This makes certain uniformity in look across the board, reducing the probability that any item will require to be thrown away because of problems. Guaranteeing the plates remain in place, the ink secret is calibrated, and all the necessary changes have been made is a taxing process when balanced out printing. Lowered pre-press steps suggest less time is needed to establish journalism this content initially. This leads to a significant velocity of turnaround time. When you need published products quickly, this is a fantastic option. Digital printing can be a lifesaver when you get an order in the nick of time.

Variable data printing, such as straight mail with individualized codes and addresses, is ideally fit for digital printing. Digital quick printing just needs four steps of design, evaluation, printing and binding to obtain whatever done. Digital quick printing has an unrivaled benefit: print on demand.

Report this page